Air Springs

Seat airsprings are designed to provide a more comfortable ride for drivers.

They decrease drivers fatigue levels by changing the hardness or resiliency of the seat caused by running conditions of the motor vehicles. Therefore driver’s seats prevent serious health risks related to driver fatigue.

Because of there ergonomic advantages, airsprung driver seats are more or less a standard feature these days, not only in buses and heavy long-distance trucks but increasingly in agricultural and construction machines such as, for example, tractors and wheel loaders.

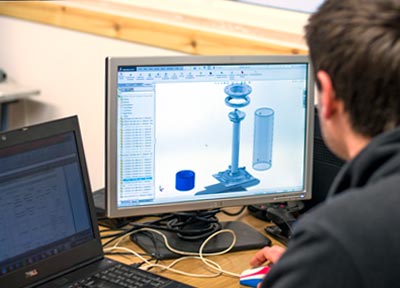

There are various designs of airspring which are made to suit the customers specified seat. You can see from the picture that we currently produce a products ranging from 110mm height (folded for placement in seat) to 140mm height. The sleeve length can be increased or decreased along with the diameter. All new designs are tested which will give a deflection graph showing the vibration reduction.

The ‘End Caps’ & ‘Pistons’ for the springs are made from glass filled nylon and are injection moulded which gives a good solid finish. The insert can be specified to match the type of tubing used in the seat.

Testing

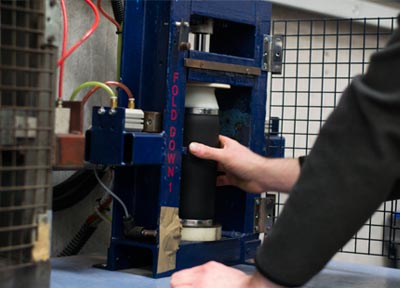

As we are an ISO 9001 certified company all of our airsprings go through a number of tests. We test all raw materials when they arrive to ensure tolerances are met.

When the insert is put into the plastic part it is then checked for any leakage, the rubber sleeves are checked when they are cut to the specific length. When the airsprings are being assembled they are inflated to 6bar pressure and held for 30 seconds and then the air is removed and the spring is folded to its finished height. Every batch has samples tested to destruction where we inflate the airspring until the sleeve or ring breaks. We usually find that the sleeve does not burst until the pressure reaches between 18-30bar depending on the size of spring. This is well over the expected pressure the spring will ever reach in its operation. If required this could be increased.